Tebur Babban Babban Gudun Hot Narke Man Fetur

Ƙayyadaddun bayanai

| Sunan Alama | GREEN |

| Samfura | Saukewa: DP500D |

| Sunan samfur | Injin Rarrabawa |

| Dandalin Hanyar Hanya | X=500, Y1=300, Y2=300, Z=100mm |

| Maimaituwa | ± 0.02mm |

| Yanayin nutsewa | AC220V 10A 50-60HZ |

| Ƙarfin Ƙarfi (L*W*H) | 603*717*643mm |

| Nauyi (KG) | 200KG |

| Mabuɗin Siyarwa | Na atomatik |

| Wurin Asalin | China |

| Garanti na ainihin abubuwan haɗin gwiwa | Shekara 1 |

| Garanti | Shekara 1 |

| Bidiyo mai fita-dubawa | An bayar |

| Rahoton Gwajin Injin | An bayar |

| Wurin nuni | Babu |

| Nau'in Talla | Kayan yau da kullun |

| Yanayi | Sabo |

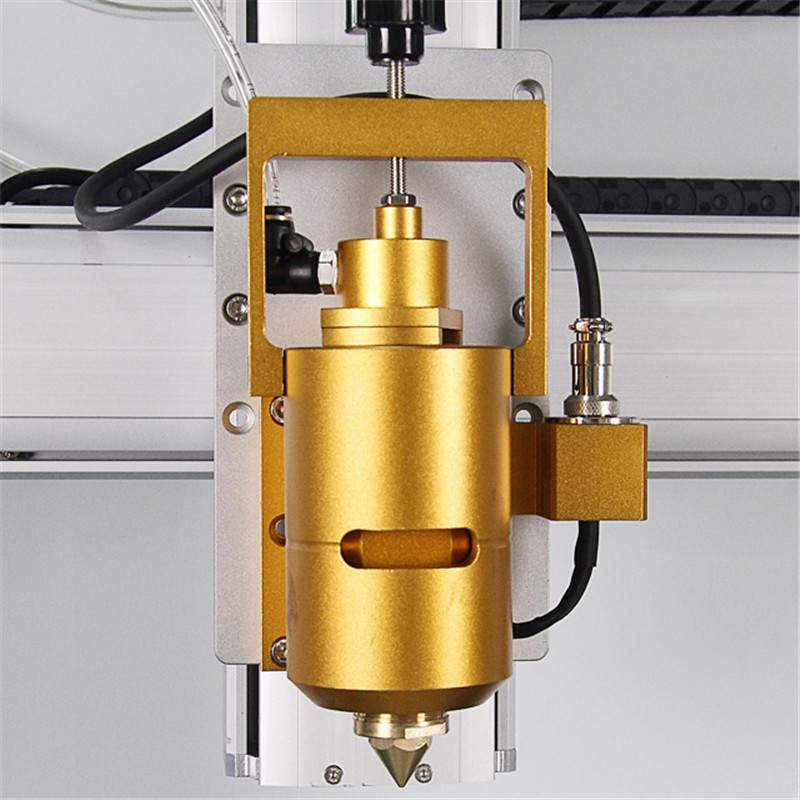

| Abubuwan Mahimmanci | Motar Servo, Nika mai niƙa, Madaidaicin dogo na jagora, Motar taci, bel ɗin aiki tare, Bawul |

| Masana'antu masu dacewa | Shuka Masana'antu, Sauran, Masana'antar Sadarwa, Masana'antar LED, Masana'antar Lantarki, Masana'antar Toy, 5G |

Siffar

● High-gudun aiki ba tare da jitter, m dissembly, sauki tabbatarwa, da kuma kudin-tasiri.

● Cikakken tantanin halitta ta atomatik tare da tsarin axis 4,

● Bayar da kayan guda ɗaya da abubuwa masu yawa,

● Menu-kore gani tare da jagorar mai aiki da matakan aiki,

● Tsarin kula da kwanciyar hankali, ƙirar injin Lean

● Daidaitacce daidaita rabo rabo, Sauƙaƙe da sauri commissioning

● Sauƙi don haɗawa cikin layin samarwa

● Babban digiri na aiki da kai , Yin rajistan ayyukan bayanai

Cikakken tsarin rarrabawa ta atomatik yana warware kowane nau'in ayyuka na rarraba daidai da dogaro. Saboda babban matakin sarrafa kansa, maganin mu na kasuwa yana haɓaka yawan aiki yayin da yake riƙe mafi inganci.

Hanyoyin Rarraba

Haɗin kai:Haɗin mannewa tsari ne na rarrabawa da ake amfani da shi don haɗa sassa biyu ko fiye tare. Ana ƙara haɓaka hanyoyin haɗin kai a matsayin filin aikace-aikace a cikin rarraba fasaha.

Ta hanyar haɗin gwiwar hanyar rarrabawa, abokan haɗin gwiwa biyu ko fiye suna haɗuwa tare. Haɗin kai mai inganci yana ba da damar haɗin kayan-zuwa-kayan ba tare da gabatar da zafi ba kuma yana haifar da lahani ga abubuwan da aka gyara. Da kyau, a cikin yanayin sassa na filastik, kunnawar saman yana faruwa ta hanyar yanayi ko ƙananan matsi. A lokacin aikace-aikacen, saman da abu ba su canzawa. Dangantaka don haka baya shafar abubuwan da ke cikin sashin kamar makanikai, aerodynamics ko aesthetics.

A matsayinka na mai mulki, tsarin ya ƙunshi matakai biyu: Na farko, ana amfani da manne sannan kuma an haɗa sassan. A cikin wannan tsari, ana amfani da manne zuwa wuraren da aka ƙayyade a waje ko cikin ɓangaren. Haɗin kai na manne yana faruwa ta takamaiman kaddarorin kayan aiki. Baya ga fannonin masana'antu iri-iri kamar fasahar likitanci, samar da kayan lantarki, gini mara nauyi, ana amfani da wannan tsarin rarrabawa akai-akai a fannin kera motoci. Ana amfani da haɗin gwiwar mannewa, misali, a cikin na'urorin sarrafa lantarki, na'urori masu auna firikwensin LiDAR, kyamarori da ƙari mai yawa.

Tuntuɓe mu da wuri-wuri a cikin lokacin haɓaka samfura. Injiniyoyinmu da masu fasaha namu na iya ba da shawara kan haɓaka kayan aikin kuma ana iya la'akari da ƙwarewar aiki. Wannan yana taimaka muku da mu don canja wurin samfuran ku zuwa jerin samarwa.

Dangane da kayan da aka zaɓa, kayan aiki da buƙatun samarwa, muna ayyana sigogin tsari don jerin samarwa tare da abokan cinikinmu. Sama da kwararru 10 daga fannonin sana’o’i daban-daban, wadanda suka fito daga chemists masu digiri na uku da injiniyoyi zuwa injiniyoyin injiniyoyi, suna nan a hannu don baiwa abokan cinikinmu shawarwari da tallafi.