Aikace-aikacen layin salula na baya-baya na SMT a cikin masana'antar lantarki ta 3C

GREEN Babban Kasuwancin Fasaha ne na ƙasa wanda aka keɓe don R&D da kera na'urorin lantarki mai sarrafa kansa da fakitin semiconductor & kayan gwaji.

Yin hidima ga shugabannin masana'antu irin su BYD, Foxconn, TDK, SMIC, Canadian Solar, Midea, da 20+ sauran kamfanoni na Fortune Global 500. Abokin haɗin gwiwar ku amintaccen don samar da ingantattun hanyoyin masana'antu.

Fasahar Dutsen Surface (SMT) shine babban tsari a cikin masana'antar lantarki ta zamani, musamman ga masana'antar 3C (kwamfuta, sadarwa, na'urorin lantarki). Yana ɗora abubuwan da ba su da guba / gajeriyar jagora (SMDs) kai tsaye a kan saman PCB, yana ba da damar haɓaka mai girma, ƙarancin nauyi, nauyi mai nauyi, babban dogaro, da samar da ingantaccen inganci.Yadda ake amfani da layin SMT a cikin masana'antar lantarki ta 3C, da mahimman kayan aiki da matakan aiwatarwa a cikin layin salula na baya-baya na SMT.

□ 3C kayayyakin lantarki (kamar wayowin komai da ruwan, Allunan, kwamfyutoci, smartwatches, belun kunne, magudanar ruwa, da sauransu) suna buƙatar ƙaramin ƙaranci, bayanan sirri, babban aiki,da sauri

iteration.SMT Lines suna aiki azaman dandalin masana'anta na tsakiya wanda ke magance waɗannan buƙatun daidai.

□ Cimma Matsanancin Ƙarfafawa da Sauƙaƙe:

SMT yana ba da damar tsari mai yawa na ƙananan sassa (misali, 0201, 01005, ko ƙananan resistors / capacitors, kwakwalwan BGA/CSP mai kyau) akan PCBs, yana rage mahimmancin allon kewayawa.

sawun sawun gaba, ƙarar na'urar gabaɗaya, da nauyi-mahimmancin taimaka wa na'urori masu ɗauka kamar wayowin komai da ruwan.

□ Bayar da Haɗin Haɗin Haɗin Maɗaukaki & Babban Aiki:

Kayayyakin 3C na zamani suna buƙatar hadaddun ayyuka, suna buƙatar babban haɗin haɗin kai (HDI) PCBs da haɗaɗɗiyar hanya mai yawa. Madaidaicin iyawar jeri na SMT shine

tushe don amintaccen haɗin haɗin waya mai yawa da kwakwalwan kwamfuta na ci gaba (misali, na'urori masu sarrafawa, ƙirar ƙwaƙwalwar ajiya, raka'a RF), tabbatar da ingantaccen aikin samfur.

□ Ƙarfafa Ƙarfafa Ƙarfafa Ƙarfafawa & Rage Kuɗi:

Layukan SMT suna isar da babban aiki (bugu, sanyawa, sake kwarara, dubawa), kayan aiki mai sauri (misali, ƙimar jeri sama da 100,000 CPH), da ƙaramin sa hannun hannu. Wannan

yana tabbatar da daidaito na musamman, ƙimar yawan amfanin ƙasa, kuma yana rage ƙimar kowane raka'a a cikin samarwa da yawa - daidai daidai da buƙatun samfuran 3C don saurin lokaci zuwa kasuwa

m farashin.

□ Tabbatar da Amincewar Samfur & Inganci:

Advanced SMT tafiyar matakai-ciki har da madaidaicin bugu, ingantaccen wuri mai inganci, sarrafa bayanan sake kwarara, da ingantattun layin layi-tabbatar da daidaiton haɗin gwiwar solder da

dogara. Wannan yana rage lahani sosai kamar haɗin gwiwar sanyi, gada, da rashin daidaituwar abubuwan, saduwa da samfuran 3C 'tsattsarin kwanciyar hankali na aiki a cikin tsauri.

yanayi (misali, girgiza, hawan zafi).

□ Daidaitawa zuwa Gaggawar Samfur:

Haɗin ka'idodin Tsarin Ma'auni Mai Sauƙi (FMS) yana ba da damar layin SMT don canzawa cikin sauri tsakanin samfuran samfura, mai saurin amsawa ga saurin haɓakawa.

bukatun kasuwar 3C.

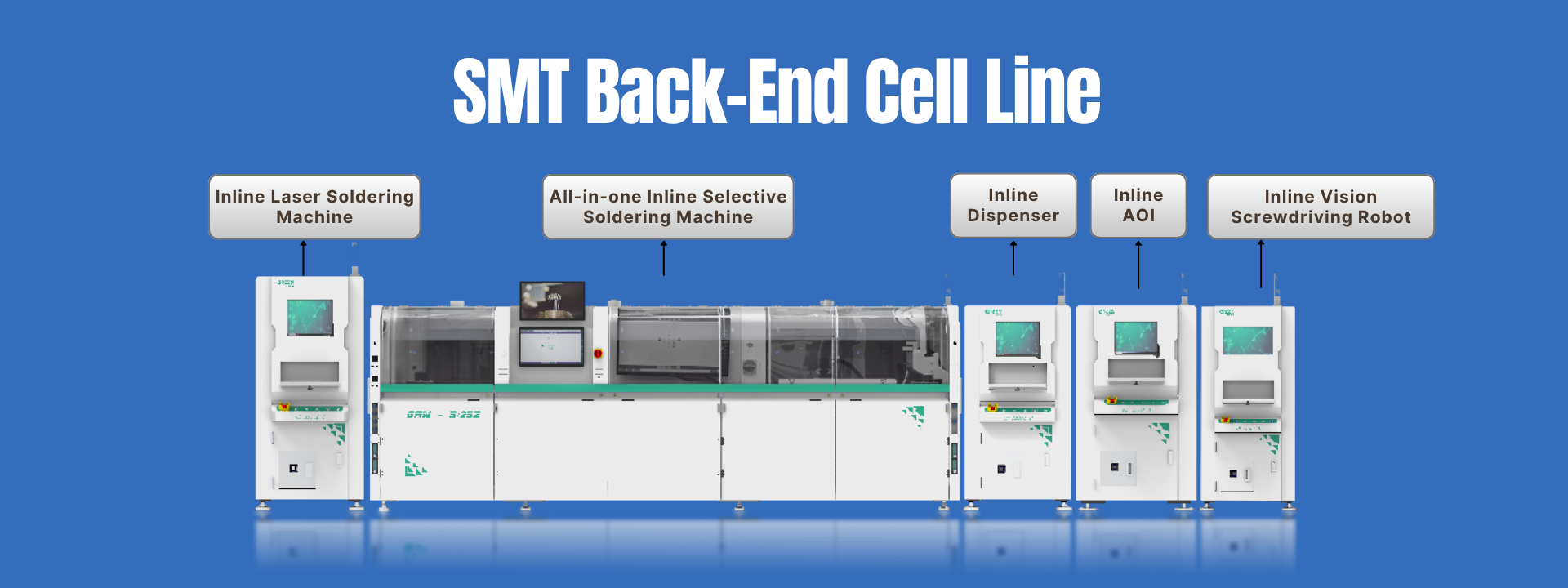

Laser Soldering

Yana ba da damar siyar da madaidaicin zafin jiki don hana lalacewa ga abubuwan da ke jin zafi. Yana amfani da sarrafawa mara tuntuɓar wanda ke kawar da damuwa na inji, guje wa matsuguni ko nakasar PCB-wanda aka inganta don filaye masu lanƙwasa/marasa daidaituwa.

Zaɓin Siyar da igiyar igiyar ruwa

PCBs masu yawan jama'a suna shiga tanda mai sake fitarwa, inda ingantaccen bayanin yanayin yanayin sarrafawa (preheating, soaking, reflow, cooling) yana narkewa da manna. Wannan yana ba da damar wetting na pads da abubuwan da ke haifar da, samar da ingantattun haɗin gwiwar ƙarfe (solder gidajen abinci), sannan ƙarfafawa akan sanyaya. Gudanar da yanayin zafin jiki shine mafi mahimmanci don ingancin walda da dogaro na dogon lokaci.

Cikakkun Cikakkun Gudun Cikin Layi Na atomatik Na atomatik

PCBs masu yawan jama'a suna shiga tanda mai sake fitarwa, inda ingantaccen bayanin yanayin yanayin sarrafawa (preheating, soaking, reflow, cooling) yana narkewa da manna. Wannan yana ba da damar wetting na pads da abubuwan da ke haifar da, samar da ingantattun haɗin gwiwar ƙarfe (solder gidajen abinci), sannan ƙarfafawa akan sanyaya. Gudanar da yanayin zafin jiki shine mafi mahimmanci don ingancin walda da dogaro na dogon lokaci.

Injin AOI

Duban AOI bayan-sakewa:

Bayan sake dawo da siyarwar, tsarin AOI (Automated Optical Inspection) yana amfani da kyamarori masu ƙarfi da software masu sarrafa hoto don bincika ingancin haɗin gwiwa ta atomatik akan PCBs.

Wannan ya haɗa da gano lahani kamar:Lalacewar solder: Rashin isassun kayan sayarwa / wuce gona da iri, mahaɗin sanyi, gadaje.Lalacewar Na'urar: Kuskure, abubuwan da suka ɓace, ɓangarorin da ba daidai ba, jujjuyawar polarity, dutsen kabari.

A matsayin kullin kula da inganci mai mahimmanci a cikin layin SMT, AOI yana tabbatar da amincin masana'anta.

Injin Lantarki na Layin Layi Mai Jagoranci

A cikin layin SMT (Surface Mount Technology), wannan tsarin yana aiki azaman kayan aiki na bayan taro, yana adana manyan abubuwa ko abubuwan tsari akan PCBs-kamar nutsewar zafi, masu haɗawa, maƙallan gidaje, da sauransu. Yana fasalta ciyarwa ta atomatik da daidaitaccen jujjuyawar jujjuyawar, yayin gano lahani ciki har da screws da aka rasa, zaren zaren giciye, da zaren zaren giciye.